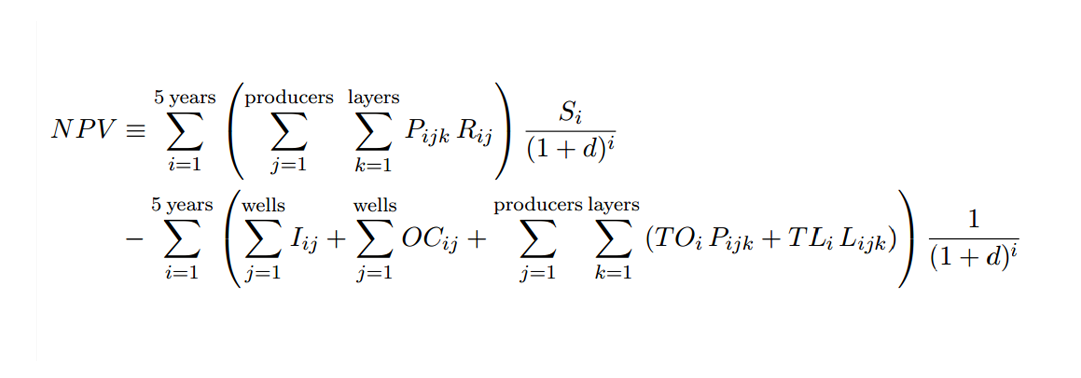

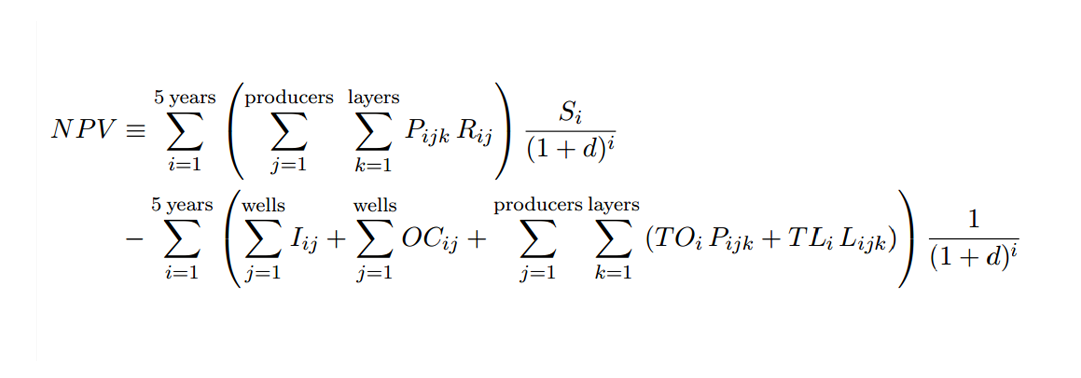

The Massive Optimizer can maximize any "gain function" you consider appropriate, typically the cumulated oil production or a carefully specified Net Present Value function.A NPV could encompass any sales, operational and capital cost, taxes and royalties, but also any cost associated to CO2 emissions (carbon footprint) and any cost saving or incomes associated to CO2 injection or retention.

where:

where:

• Pijk denotes oil production for well j and layer k for year i, as calculated by the Digital Behavior Twin.

• Rij denotes margin after tax and royalties for well j and year i.

• Si denotes the oil sale price per barrel for the field concerned for year i.

• d denotes the yearly discount rate (% per year).

• Iij denotes investment spent for well j (producer or injector) during year i.

• OCij denotes the operating costs spent for well j (producer or injector) during year i.

• Lijk denotes the liquid production for producer j and layer k during year i, as calculated by the Digital Behavior Twin.

• TOi denotes the liquid treatment cost per barrel during year i.

• TLi denotes processing treatment cost per barrel of oil during year i.

where:

where: